Santos PNG Asset Hierarchy Update

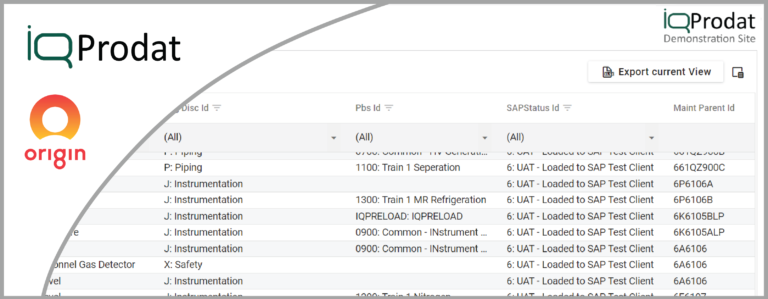

Information Quality’s Asset Management and Maintenance Master Data expertise were engaged to update the asset hierarchy to align to the ISO 14224 framework for the Santos PNG assets. This included evaluating and reassigning maintenance where appropriate.