Effective maintenance and reliability management must be implemented to realise the full potential of any plant or facility safely. Information Quality assist clients to optimise asset maintenance; leveraging lessons learned and best practice to ensure peak plant reliability and maximum return on investment.

Information Quality are experts in the development of optimised maintenance regimes on new facilities, together with running programs to deliver efficient optimised and where appropriate, rationalised maintenance on existing operating assets. Using a robust set of fundamental structures, processes and in-house applications, Information Quality offer a full suite of maintenance and reliability management services across a broad range of industries including New Energy, Renewables, Oil and Gas, Mining, Defence, Utilities, and Infrastructure

“The sure way to increase productivity is to better administrate man and machine”

W. Edwards Deming

Maintenance Master Data & ERP Configuration

With knowledge born of decades of experience, Information Quality perform all aspects of the computerised maintenance management system configuration and maintenance master data development & load.

Leveraging data created during engineering and utilising advanced techniques, IQ develop fully compliant maintenance builds integrated with all client ERP modules including Finance, HR, Supply Chain & Logistics to provide a holistic solution. In addition, IQ have specific expertise to support your SAP transition from ECCC6 to S4HANA.

Maintenance & Reliability Strategies

Information Quality personnel have extensive experience in the definition, development and implementation of reliability management strategies, processes and procedures, including the facilitation of maintenance and reliability studies and workshops.

Information Quality have the experience and expertise to perform or mediate all aspects of maintenance and reliability studies including but not limited to FMECA, RAM, RCM, RBI, SIL & IPF.

Maintenance Systems Audit & MOC

Information Quality perform maintenance systems audit services to confirm optimal performance of client plant maintenance and provide recommendations identifying opportunities to optimise or rationalise maintenance builds and work management processes.

Clients regularly leverage IQ’s management of change processes and procedures to ensure the plant maintenance database (CMMS) remains a true reflection of the physical plant and contains all mandatory and preventative maintenance requirements.

Safety & Integrity Compliance

Information Quality are highly experienced in the regulatory and statutory requirements for the operation and maintenance of plants across multiple industries.

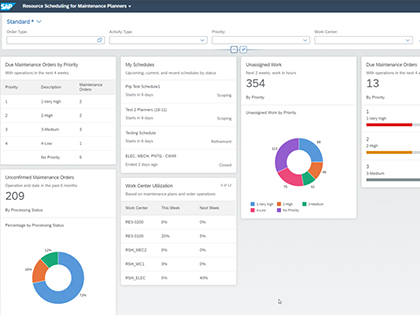

This experience coupled with extensive expertise in maintenance systems and development allows Information Quality to effectively assist clients with the development of measure to demonstrate plant safety and compliance and maintain license to operate. This includes development of performance standards aligned to facility safety cases, together with the development of interactive dashboards to demonstrate SCE and TI master data compliance and maintenance execution compliance.

Spare Parts Management

Spare parts management and optimisation is a foundation to cost effective operating processes. Information Quality liaise with vendors, operators and maintainers to ensure that spare parts are effectively managed, tracked and rationalised, resulting in maximum probability coverage while maintaining minimum warehousing levels.

IQ enjoys extensive experience in spare parts cataloguing, the development of Bills of Materials (BOM) and conducting spare parts & materials management process reviews & optimisation.

Maintenance Planning & Work Management

IQ Maintenance Planners and Schedulers are well versed in the efficiencies of effective work management to optimise maintenance execution.

IQ regularly conduct work management process audits and present recommendations to improve maintenance execution, ensuring plants operate at optimal production capacity without compromising safety. IQ also provide industry leading planning & scheduling training for client personnel, together with industry standard planning software implementation and training, including Primavera, Prometheus and SAP.